Classifier

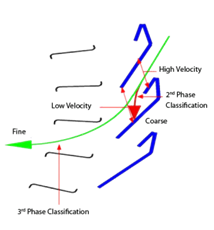

We are one of the leading manufacturer and supplier of LV Classifiers. These classifiers are manufactured using high-grade raw material, which is procured from the reliable vendors of the market. In addition to this, to ensure the international standards and norms, these classifiers are tested on various well-defined parameters.LV Classifier and its unique separation concept The principle of classification is same for all the classifier but what makes LV classifier unique is its three phase classification compared to single phase classification in modern classifier.

1st phase classification:

The first phase classification takes place right at the feeding point, the coarse and grits fall down in the air stream and shall go back to mill for further grinding via reject air slide. This separation saves a lot in term of pressure drop across the separator as well power consumption. The grits get separated from the fines before reaching LV pockets and rotor (2nd and 3rd phase classification).

2nd phase classification

The second phase classification takes place in LV pockets due to velocity change and needs no energy to do that. This second phase classification removes a significant amount of coarse material before reaching the rotor for final separation. The 1st and 2nd phase classification reduces dust load going to the rotor and in return gives

– Low power consumption

– Low pressure drop

– High separation efficiency

3rd phase of classification

Third phase of classification takes place at rotor. As most of the coarse is already separated in feeding point and LV pockets, the rotor has much less work to accomplish and consequently the separation efficiency is the maximum possible in present range of separator.