Engineering services

Our organization is counted among the firms engaged in providing Retrofitting Services. These services reduce the power consumption and enhance the production capacity. By providing better residue control on the product, these services provide better particle size distribution of the product. The services offered by us are rendered in compliance with the exact requirements of the customers using high-grade raw material and advance machines.a layout of a cement plant is a logical and practical arrangement of the various sections and stages of the plant in a process sequence starting with receipt of raw materials and ending with final dispatch of product and the processes that would help in production, in an efficient and effective manner, using optimum inputs interms of space, raw materials, fuel, energy and man power, along with minimum disposal of waste

LNVT E&I CAPABILITIES

LNVT’s Electrical & Instrumentation team is a fully integrated entity offering sustainable value with products and solutions encompassing complete plant electrification, and plant-wide instrumentation with most optimized automation solutions. The process, production and practical maintenance experience combined with that of LNVT’s Electrical & Instrumentation customised engineering, benefits the customers with a one stop source for design, engineering, supply, installation, commissioning, training and life-cycle support services. This not only reduces overall project cost, but also results in an effective and reliable total integration of plant.

Bhavya cements 132 kv Switchyard

MCC Panel Supplied to RAK Cements

Variable frequency drive – JK Lakshmi Cements Sirohi

Cable tray engineering – Ghorahi Cements

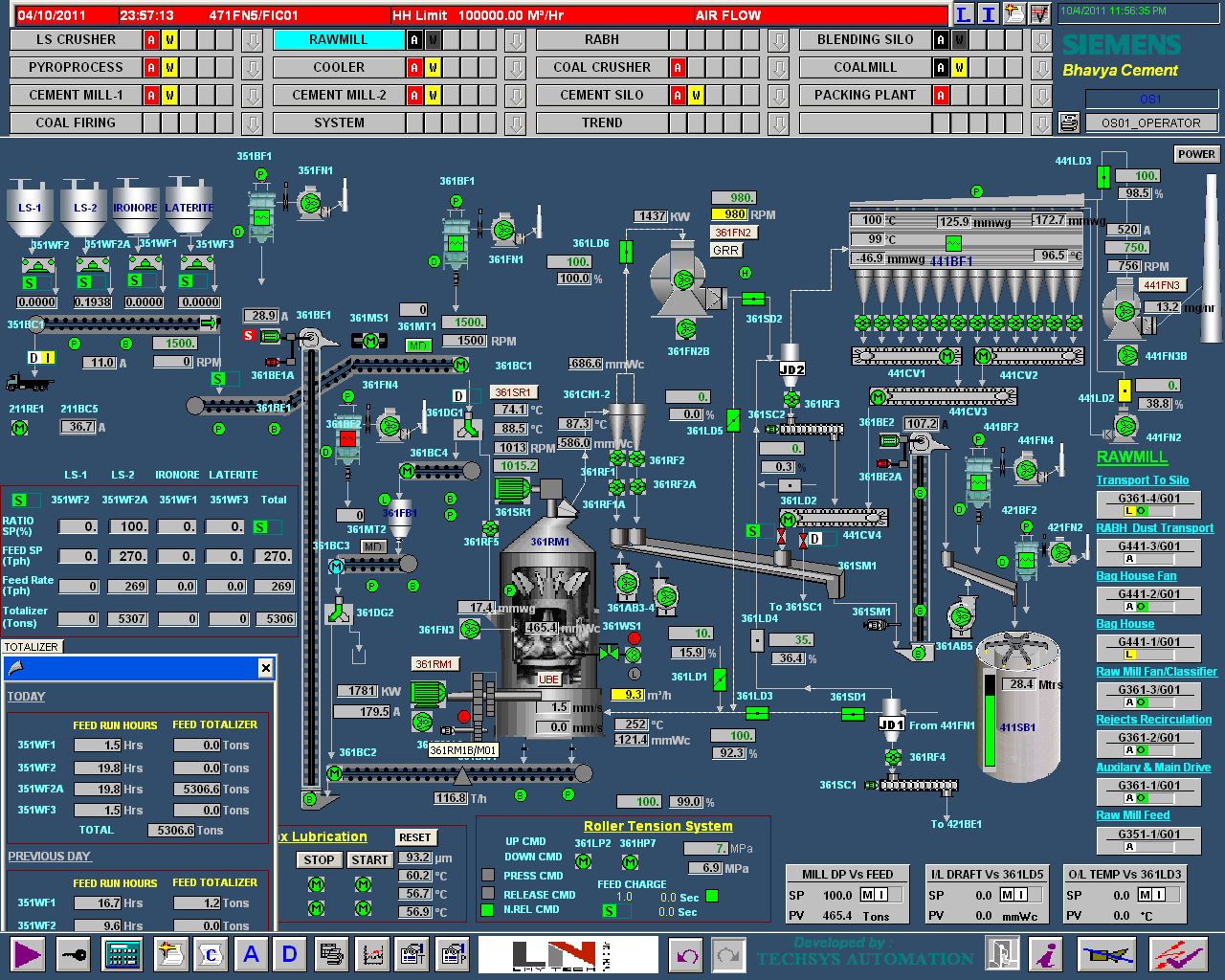

Snap Shot –Rawmill – Bhavya cements

Major Projects Executed:-

1. JK Laksmi cements – Sirohi – 4 Grinding units

2. . JK Laksmi cements – Sirohi – Raw mill

3. RAK Cement – Dubai – Coal grinding

4. Bhavya cements – 4500 TPD Complete Turnkey

4. Citycement – Roller press 1 & 2 – Saudi Arabia

5. JK lakshmi Cements – Kalol 1&2 & Jhajjar – Grinding unit

6. JK lakshmi Cements Durg – Rawmill & Coamill, Slagmill & Cement mill

7. Ghorahi cements – Nepal – Grinding unit

8. CG cement – Nepal – Grinding unit

9. Udaipur Cement works – Grinding unit

10. Dig vijay Cements – Coal Grinding (Supply and Erection)

PMCC PANEL – ELECTRICAL ROOM

11KV HT PANEL – ELECTRICAL ROOM

11KV HT CAPACITOR PANEL – ELECTRICAL ROOM

CABLE TRAY ROUTING – ELECTRICAL ROOM

CABLE TRAY ROUTING – ALONG THE CONVEYOR

LNVT-SINOMA’s “INHOUSE ELECTRICAL ENGINEERING” expertise for complete Electrical and Instrumentation packages, was once again established in the Indian Cement industry for the recently commissioned Petcoke grinding system for Shree Digvijay Cement Ltd .

This order was awarded to LNVT on EPC basis and the supply included 11KV HT panels, PMCC panels. HT & LT Capacitor panels, Distribution transformer and complete Erection / testing / commissioning. The order was completed and commissioned within the contractual period and the system has been running satisfactorily.

criteria for developing a compact layout were fulfilled at JKLC Kalol Cement Grinding Unit :

- Least power consumption as compared with other grinding units.

- Easy accessibility and approach to all equipments with good house keeping.

- Reduction in the length of Ducts, Chutes, reducing the number of Bends across ducts / pipelines, thereby minimizing wear and tear and lowering the pressure drop.

- Effective venting was made to ensure dust-free environment, prevent spillage & enable smooth flow of material, especially in Conveyors and a pollution-proof layout was inturn produced.