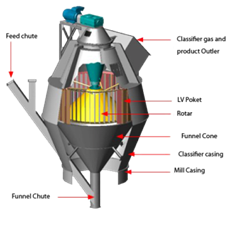

Concept of LV Classifier

LV Classifiers are applied to vertical mills and ball mills. References exhibit more than 500 sets supplied to all over the world. LV Classifier produces higher production rate about 10-20% and less specific power consumption about 1.5-5kWh/t, compared with other Separators.

1. LV Pocket

Special construction of LV the Pocket works as coarse material trap. So that coarse material carried by the gas from the mill is prevented from mixing with the fines. Coarse material caught by the LV Pocket moves down by gravity along the LV Pocket to the funnel cone without mixing with the fines. This construction makes “no fine in coarse, no coarse in fine”. Since material on mill table has smaller fine portion, vibration becomes smaller.

2.Funnel Cone

Funnel cone is not only to collect reject from LV Pocket and to feed material to table but also to control gas speed distribution between Classifier casing and funnel cone. This makes it possible to obtain preferable gas velocity between casing and funnel cone and to eliminate material internal circulation. smaller by reducing internal circulation of material.

3.Funnel Chute

Reject from funnel cone feeds back to center of mill table through funnel chute. The special funnel chute is designed to feed material on to mill table smoothly with minimum height.

This also contributes to reduce mill vibration.