Walking Floor

Technical Characteristics:

- Designed with standard modules

- Grate plates are pushed by horizontal hydraulic force, providing for reliable and steady operation

- Seals between grate plates are carefully casted, effectively preventing clinker leakage; The fixed, inclined inlet zone design prevents formation of snow men

- Self-adjusting automatic valves for controlling the air flow are placed below the grate plates, avoiding cooling air flow to become interrupted

- Choice between hammer crusher or roller crusher; the roller can be installed in the middle or at the end of the cooler

- With a roller crusher in the middle, large clinker pieces or chunks from fallen kiln coating can continue to cool after being crushed, which provides for increased throughput at lower overall exit temperature compared to crushers positioned at the end of the cooler.

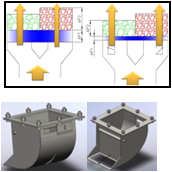

Leakproof seal structure:

- By using combination of concave, convex cast structure seal is more rugged, reliable, and can effectively prevent leakage of material .

- The entire grate altar linens wind chamber unit is relatively uniform.

- Stable by the flow control valve pressure difference of each unit, so as to ensure a constant air volume.

Clinker Cooler:

Coolers are used with rotary kilns to rapidly cool hot clinker or other materials exiting the kiln.More…

Walking Floor :

roller crusher in the middle, large clinker pieces or chunks from fallen kiln coating can continueMore…

SType Cooler Push Bars:

Modular Design, Convenient installation and maintenance, easy replacement of spare parts. More…